Superior Quality – Unmatched Service – Over 30 Years of Excellence

With over 30 years of experience, E-Z Mix is Southern California's trusted manufacturer of SPEC MIX® products. As an industry leader, we take pride in delivering high-quality SPEC MIX® Mortars and Grouts, along with additional specialized products developed to meet the demands of construction professionals.

Our Product Lines Include:

- SPEC MIX® Polymer-Modified Stone Veneer Mortars (SVMS) – Engineered for high-performance installations, delivering exceptional bond strength and long-term durability in adhered veneer installations.

- SPEC MIX® Polymer-Modified Thin-Set Mortars – Developed for high bond strength on tile installations over challenging substrates.

- SPEC MIX® Scratch & Brown Fibered – Enhanced stucco basecoat solutions.

- SPEC MIX® Mortars & Grouts – Type S and Type M – For CMU structural masonry construction and grouting joints in adhered veneer applications, available in multiple colors.

- SPEC MIX® IWR & Lime Replacement (LR) Mortars and Grouts – Type S and Type M – Formulated with integral additives to enhance resistance to moisture intrusion and efflorescence.

Quality and Consistency You Can Trust

Our on-site Quality Control and Assurance team rigorously tests all materials to ensure consistent compliance with the American Society for Testing and Materials (ASTM) and American National Standards Institute (ANSI) standards and all relevant building codes. All products are independently tested and certified by third-party laboratories to verify quality and performance integrity.

Our Commitment to Excellence

At E-Z Mix, we have spent years building a solid reputation for delivering industry-leading products backed by exceptional customer service. Our commitment to quality and innovation continues to drive our success, and our dedicated and knowledgeable team is always ready to assist you with your specific project requirements.

SPEC MIX® SVMS – STONE VENEER MORTAR SYSTEM

Formulated for Strength, Durability, Superior Bonding:

SPEC MIX® Polymer-Modified Stone Veneer Mortars (SVMS) provide exceptional bond strength, excellent workability, enhanced resistance to moisture intrusion and efflorescence, making SVMS the preferred bonding mortars for adhered veneer installations.

Designed for a Wide Range of Veneer Installations:

- Natural Stone

- Manufactured Stone Veneer

- Dry Stack

- Thin Brick

- Planks and Tiles

Developed for architects and contractors, SPEC MIX® SVMS addresses the industry's evolving demands by delivering exceptional bond strength, advanced sag resistance, and verified compliance with The Masonry Society (TMS) 402/602-22, ANSI A118.4, ANSI A118.11, and ANSI A118.15 shear bond requirements.

Unmatched Performance & Reliability

Unlike traditional masonry mortars that rely solely on mechanical bonding, SPEC MIX® SVMS combines mechanical and chemical bonding to significantly increase adhesion to concrete, masonry, properly prepared wood, metal studs, and rigid insulation substrates. Its advanced polymer-modified formula chemically reacts with both the veneer unit and substrate, forming a molecular bond for long-lasting durability and reduced risk of failure.

Industry-Leading Warranty

A key advantage of SPEC MIX® SVMS is its industry-leading warranty, providing comprehensive coverage from the brown coat to the veneer. This seamless integration within the SVMS wall system ensures a durable and reliable installation.

SPEC MIX® SVMS provides exceptional bond strength, advanced durability, and industry-leading warranty coverage, making it the proven and trusted choice for architects and contractors seeking high-quality adhered veneer wall systems.

Specify with SPEC MIX® SVMS for proven results. Learn more: www.ezmixinc.com/SVMS

COMPLIANT MORTARS FOR VENEER INSTALLATIONS

TMS 402/602-22: Veneer System Code Updates

The TMS 402/602-22 standard, recently adopted into the 2024 International Building Code (IBC) and scheduled for inclusion in the 2025 edition of the California Building Code (CBC), introduces key updates that directly affect adhered veneer mortar systems. These revisions offer architects and contractors improved prescriptive guidance and more flexible engineered design options aligned with modern construction practices.

A major advancement in the code is the formal recognition of polymer-modified mortars that meet ANSI A118.4 and A118.15 standards. These mortars deliver superior bond strength, improved workability, and long-term durability. As these standards are adopted nationally and statewide, adhered veneer systems will need to meet more rigorous performance benchmarks to ensure higher levels of structural integrity, moisture resistance, and consistent installation across residential and commercial construction.

Understanding Modified Mortars

Modified mortars—also called polymer-modified mortars—are manufactured to meet ANSI A118 standards. They include Portland cement, graded sand, and polymers to enhance performance in:

| Shear Bond Strength | Sag Resistance | Water Retention | Workability | Setting Times |

The performance of modified bonding mortars depends primarily on the level of polymer modification, typically measured by ANSI A118 standards:

| ANSI A118.1 Non-modified |

ANSI A118.4 Minimally modified |

ANSI A118.11 Modified |

ANSI A118.15 Extremely Modified |

Polymer-modified adhered veneer mortars deliver the performance required for modern masonry systems, which increasingly rely on veneer installation across residential and commercial construction. All SVMS Bonding Mortars use polymer-modified compounds and are not intended for grouting.

Advantages of Extremely Modified Mortars:

| High shear bond strength and long-term durability |

Capable of holding large and heavy veneers securely in place |

Advanced workability and reduced cracking potential |

Superior resistance to efflorescence and reduced water permeability |

Suitable for submerged applications in accordance with ANSI A118.15 |

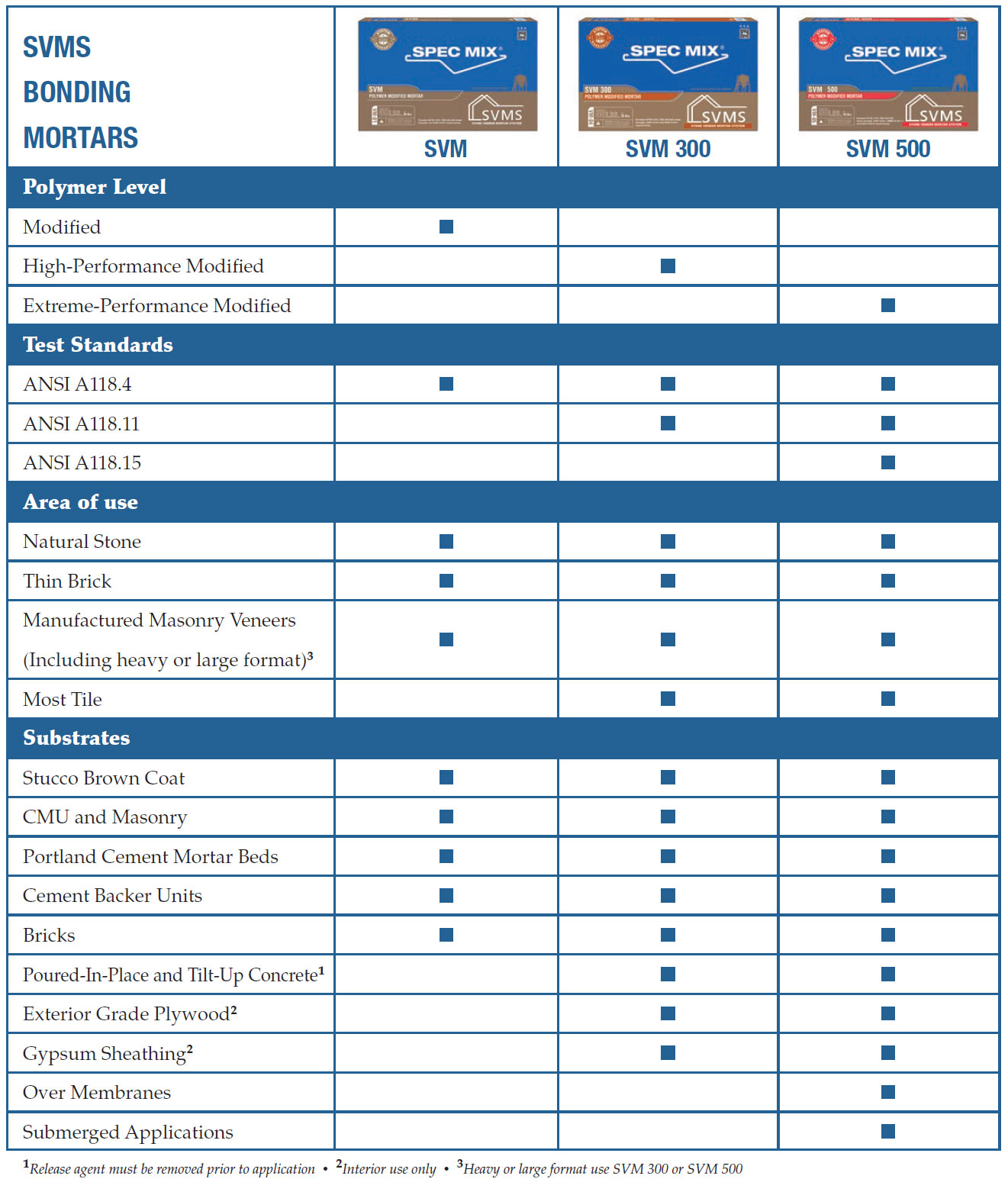

SPEC MIX® SVMS BONDING MORTARS

Select the Appropriate Bond Strength and Sand Blend for Specific Adhered Veneer Installations

SPEC MIX® SVMS Bonding Mortars provide a versatile range of polymer-modified mortars and sand blends, giving applicators and design professionals the flexibility needed for a wide range of adhered veneer installations.

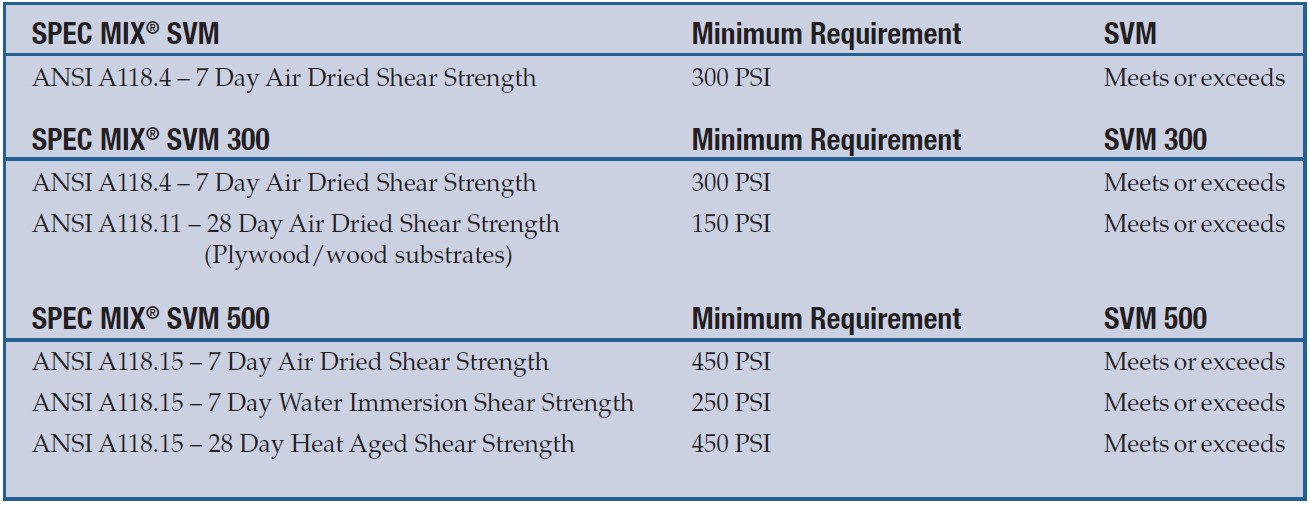

Performance

All SPEC MIX® SVMS Bonding Mortars incorporate polymer-modified additives to enhance mortar performance. The product line includes three bonding mortar tiers that meet or exceed ANSI A118 testing standards:

| SVM – Modified SVM 300 Exceeds ASTM C270, TMS 402/602-22 shear strength, and ANSI A118.4 requirements |

High Performance SVM 500 Exceeds ASTM C270, TMS 402/602-22 shear strength, and ANSI A118.4 and ANSI A118.11 requirements |

Extreme Performance Exceeds ASTM C270, TMS 402/602-22 shear strength, and ANSI A118.4, ANSI A118.11, and ANSI A118.15 requirements |

Sand Type

SPEC MIX® SVMS Bonding Mortars are available in two sand blends:

- Standard – Coarse, medium-thick bed sand conforming to ASTM C144

- Fine – Similar to thin-set mortars; used in veneer applications requiring reduced bed thickness

Colors

SPEC MIX® SVMS Bonding Mortars are available in standard and custom colors.

Standard base colors: white, grey, medium tan

Packaging

- 50 lb. (22.6 kg) bags – Available in fine or coarse sand

- 94 lb. (42.6 kg) bags – Available in coarse sand

Coverage (approximate)

Approximate coverage per 50 lb. and 94 lb. bag. Coverage may vary depending on the type of veneer, ambient or surface temperature, surface preparation, and/or mixing or application methods:

| Trowel Size | 50 lb. (22.6 kg) bags | 94 lb. (42.6 kg) bags |

|---|---|---|

| 1/4” x 3/8” | 60–70 ft² | 112–132 ft² |

| 1/2” x 1/2” | 40–50 ft² | 75–94 ft² |

| Masonry Method | 30–35 ft² | 56–66 ft² |

Storage

- Store bags in a cool, dry location

- Keep out of direct sunlight and away from contact with the ground or concrete

- Protect bags from weather and other potentially damaging elements

SPEC MIX® STONE VENEER MORTAR

PROPER ADHERED VENEER INSTALLATION PRACTICES

Best Practices for a Successful Adhered Veneer Installation

Selecting the right polymer-modified mortar is crucial for a durable adhered veneer installation, but proper installation techniques and compliance with local building codes are equally important. As adhered veneer systems evolve, traditional mortars and methods that once worked will no longer meet updated building code requirements, leading to premature failure if used today.

Click here for additional resources on proper veneer installation.

To Ensure a Strong, Long-Lasting Veneer Installation, Follow These Proven Techniques:

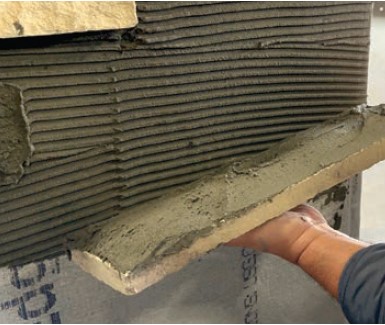

- Use a Wet-to-Wet Bond – Apply mortar while both veneer and substrate are fresh and moist

- Back Butter Each Veneer – Avoid spot bonding and other improper bonding methods; ensure full mortar coverage on the back of every veneer.

- Ensure 100% Coverage – On both the veneer and the properly prepared substrate.

- Slake the Mortar –After initial mixing, allow the mortar to rest (slake) for at least 5 minutes, then remix before application to fully activate polymers and ensure optimal workability, consistency, and bond performance.

Surface Preparation and Application Tips

- Clean the Surface – The substrate and back of the veneer receiving bonding mortar must be free of dirt, oil, paint, dust, debris, residue, release agents, or anything that hinders proper bond.

- Proper Troweling Technique – When using a notched trowel:

- Horizontal Applications – Comb mortar in straight lines for stronger adhesion.

- Vertical Applications – Always create horizontal ridges. Do not swirl mortar; this can trap air and weaken the bond.

- Movement and Control Joints – Ensure proper expansion joints are in place to prevent buckling and tenting.

- Verify Veneer and Grout Colors – Confirm color match through a job site mock-up prior to installation.

Follow Manufacturer Guidelines

Each veneer product has specific installation requirements. Follow the manufacturer’s recommendations.

Some veneers may not be suitable for exterior or vertical wall installations.

Proper installation with wet–to–wet bond

Spot bonding – improper application

Improper application not 100% coverage leaves air pockets – not wet–to–wet bond

Understanding Veneer and Modified Mortar Types

Why Polymer-Modified Mortars Matter in Adhered Veneer Installation

Selecting the correct SPEC MIX® SVMS Bonding Mortar is critical to preventing failure and ensuring long-term durability. Veneer size, weight, density, and porosity (absorption) directly affect bonding demands and mortar selection. Understanding ANSI A118.4 and A118.15 standards is essential to properly match mortar type to veneer conditions, installation methods, and jobsite performance requirements. To better understand ANSI standards, visit www.ansi.org.

Matching Mortar Strength to Veneer Type

For Heavier Manufactured Stone Veneers, Large-Format Porcelain Tiles, Natural Stones:

- Manufactured Stone Veneers – These units are increasing in size and weight, requiring mortars with exceptional bond strength and advanced sag resistance.

- Large-Format Porcelain Tiles and Natural Stones – These materials often vary in density and porosity, requiring a high- or extreme-performance modified mortar to ensure proper adhesion and long-term durability.

- Mortars That Meet ANSI A118.15 Requirements – SVM 500 is the only bonding mortar in the SVMS lineup that meets these requirements. It delivers exceptional bond strength and robust sag resistance for large, heavy, dense, or natural stone-cut veneers. Mortars meeting ANSI A118.15 requirements are also code-compliant for submerged water installations.

For Lighter Manufactured Stone Veneers and Thin Brick Veneers

- Smaller Veneer Units – These are lighter-weight and more porous, allowing for the use of mortars that meet ANSI A118.4 standards.

- Mortars That Meet ANSI A118.4 Requirements – These provide durable adhesion and are designed for materials that readily absorb and bond to the mortar bed.

Examples of Veneers for ANSI A118.4 Bonding Mortars: Use SVM

|

|

SVM

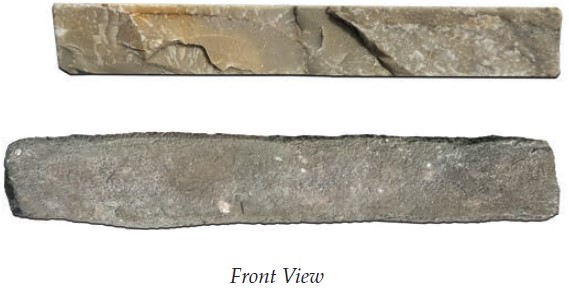

Veneers with Moderate Absorption Rates (5%–10%) – These include smaller and/or lighter-weight veneers such as:

- Manufactured Stone Veneers – Smaller sizes, such as 4” x 8”, 6” x 10”, and 2” x 12”

- Thin Natural Stones – Smaller sizes, approximately ½” thick and 5”–8” long

- Thin Brick – Manufactured or cut units that are not high-fired

Examples of Veneers for ANSI A118.11 Bonding Mortars

|

|

SVM 300

Veneers with Low Absorption Rates (2.5%–4%) – These veneers are less porous and include moderately sized, or weighted veneer units, such as:

- Manufactured Stone and Plank Veneers – Approximately 8" x 36" to 12" x 24"

- Thin Brick – Medium-fired to high-fired

- Medium-Sized Natural Stone Veneers – Z Panels, Quick-Fit Panels

Examples of Veneers for ANSI A118.15 Bonding Mortars

|

|

SVM 500

The Heavier

The Better

PLATINUM

THIN–SET

Veneers with Very Low Absorption Rates (0.5%–2.9%) – These veneers are non-porous and dense and include larger veneers nearing the code-defined weight limit, such as::

- Natural Stone Veneers – Approaching 15 lbs/sf

- High-Fired or Iron Spot Brick Veneers – Suitable for installations requiring ANSI A118.15 performance

- Large or Heavy Manufactured Veneers – Nearing the codedefined weight limit

- Longer Plank-Style Veneers – Often used in contemporary veneer installations requiring wider formats

- Glass, Porcelain, or Dense Tile Materials – Including glass tiles, porcelain tile, and dense stone

Note: For glass tiles or translucent installations, use SPEC MIX® Thin-Set Platinum, a polymer-modified mortar that meets or exceeds ANSI A118.15 requirements and is specifically formulated for tile-bonding performance.

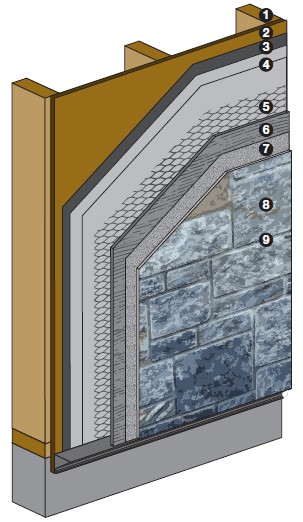

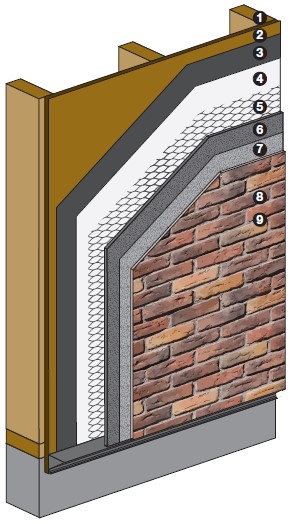

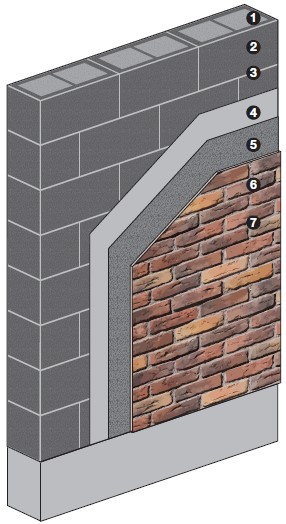

SPEC MIX® SVMS WALL SYSTEM WARRANTIES (DETAILED DRAWINGS)

SPEC MIX® SVMS Bonding Mortars, SPEC MIX® Type S and Type M Mortars, and SPEC MIX® Scratch and Brown Fibered work together as part of a high-performance system that qualifies for extended wall system warranties.

These diagrams illustrate proper product placement for adhered veneer installations. All SPEC MIX® components must be installed per local building codes and applicable ASTM and ANSI standards. Warranty coverage depends on the combination of SPEC MIX® products used. Click here for more industry guidance on proper veneer installation.

SPEC MIX® SVMS over Spec Mix Scratch and Brown Fibered Wall System Warranty

Veneers with Very Low Absorption Rates (0.5%–2.9%) – These veneers are non-porous and dense and include larger veneers nearing the code-defined weight limit, such as::

- - Wood or Steel Framing – Code-compliant product by alternate supplier

- - Exterior Sheathing – Code-compliant product by alternate supplier

- - Air and Water Barrier – Code-compliant, meeting ICC-ES AC212 requirements by alternate supplier1

- - Secondary Weather-Resistant Barrier – Two Layers, code-compliant product by alternate supplier

- - Lath – Code-compliant product by alternate supplier

- - SPEC MIX® Scratch and Brown Fibered2

- - SPEC MIX® SVM, SVM 300, SVM 500 Bonding Mortar

- - Adhered Veneer – Code-compliant product by alternate supplier

- - SPEC MIX® Mortar for Grouting Joints and SVMS Adhesive Sealant

Mortar Options:

SPEC MIX® Type S / SPEC MIX® IWR Type S / SPEC MIX® LR or LR Plus Type S

SPEC MIX® SVMS over Approved One Coat Wall System Warranty

- - Wood or Steel Framing – Code-compliant product by alternate supplier

- - Exterior Sheathing – Code-compliant product by alternate supplier

- - Air and Water Barrier – Code-compliant, meeting ICC-ES AC212 requirements by alternate supplier1

- - Foam Sheathing – Code-compliant product by alternate supplier

- - Lath – Code-compliant product by alternate supplier

- - Approved One Coat Base Coat2,3

- - SPEC MIX® SVM, SVM 300, SVM 500 Bonding Mortar

- - Adhered Veneer – Code-compliant product by alternate supplier

- - SPEC MIX® Mortar for Grouting Joints and SVMS Adhesive Sealant

Mortar Options:

SPEC MIX® Type S / SPEC MIX® IWR Type S / SPEC MIX® LR or LR Plus Type S

1 Use of a code–compliant and approved water and air barrier, meeting ICC–ES AC212 requirements and provided by alternate supplier, qualifies for an additional five-year limited warranty.

2 PMP Concrete Bonder & Fortifier Admixture may be used to improve base coat tensile and flexural strength. Using PMP Concrete Bonder & Fortifier Admixture qualifies for an additional five-year limited warranty.

3 For Approved One Coat Base Coat, please contact E–Z Mix Technical Support: tech.support@ezmixinc.com

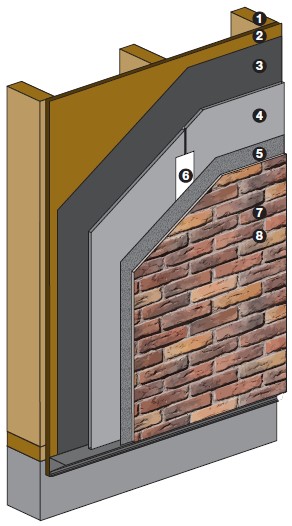

ADDITIONAL SPEC MIX® SVMS WALL SYSTEM WARRANTIES

SPEC MIX® SVMS offers one of the industry’s leading warranties for adhered veneer when SPEC MIX® SVMS Bonding Mortars are used over other approved alternative wall assemblies. Common substrates include CMU, code-compliant cement board, brick, and tilt-up or poured-in-place concrete.

Approved Cement Board Wall System Warranty

- - Wood or Steel Framing – Code-compliant product by alternate supplier

- - Exterior Sheathing – Code-compliant product by alternate supplier

- - Exterior Veneer Approved Board – Code-compliant product by alternate supplier*

- - SPEC MIX® SVM, SVM 300, SVM 500 fine skim coats

- - SPEC MIX® SVM, SVM 300, SVM 500 fine bonding mortars

- - Control Joint Treatment – Code-compliant product by alternate supplier

- - SPEC MIX® SVM, SVM 300, SVM 500 Bonding Mortar

- - Adhered Veneer – Code-compliant product by alternate supplier

- - SPEC MIX® Mortar for Grouting Joints and SVMS Adhesive Sealant

Mortar Options:

SPEC MIX® Type S / SPEC MIX® IWR Type S / SPEC MIX® LR or LR Plus Type S

CMU, Tilt-Up, and Poured-in-Place Wall System Warranty

- - PMP Spec Concrete 3000 or PMP Grout Additive with CMU

- - CMU5, Tilt-Up, and Poured-in-Place*

- - SPEC MIX® Mortar for bedding CMU

- - SPEC MIX® SVM, SVM 300, SVM 500 skim coats

- - SPEC MIX® SVM, SVM 300, SVM 500 Bonding Mortars

- - Adhered Veneer – Code-compliant product by alternate supplier

- - SPEC MIX® Mortar for Grouting Joints and SVMS Adhesive Sealant

Mortar Options:

SPEC MIX® Type S or M / SPEC MIX® IWR Type S or M / SPEC MIX® LR or LR Plus Type S or M

5 Using Angelus Block Co., Inc., CMU qualifies for an additional ten-years limited warranty. This extension is independent and cannot be combined with coverage offered by components noted in footnotes 1 or 2..

* NOTE: All substrates must be free of oil, paint, release agents, dirt, or any material considered a bond breaker. These must be removed prior to installation of bonding mortar by sandblasting or bead blasting. This is required. Pressure washing is not acceptable.

THIRD-PARTY CERTIFIED TESTING

Proven Performance and Trusted Quality

E-Z Mix delivers consistent, third-party verified quality backed by trusted performance. SPEC MIX® SVMS Bonding Mortars are engineered for demanding adhered veneer installations, delivering superior adhesion, durability, and longterm reliability. Choosing E-Z Mix means specifying tested products with proven performance and code compliance.

- Extensively Tested for High Performance – E-Z Mix products undergo rigorous in-house and third-party testing to verify strength, consistency, and reliability.

- Third-Party Certified – An accredited laboratory verifies all products to confirm compliance with industry standards and building codes.

- Built on Integrity – E-Z Mix manufactures high-quality, performance-driven bonding mortars that professionals trust for their most demanding projects.

Submerged Water Installation Requirements

For installations exposed to continuous water immersion, such as pools, fountains, or water features, only use polymermodified mortars that are verified by an accredited third-party laboratory, clearly listed on technical data sheets, and labeled as meeting the performance requirements of ANSI A118.15.

www.ezmixinc.com – Email: info@ezmixinc.com

Product Data Sheets and Certifications Available: All products comply with ASTM, ANSI standards, IBC, and CBC requirements.

SPEC MIX® SVMS POLYMER-MODIFIED BONDING MORTARS

SVM 500

SPEC MIX® SVM 500 is the proven architect-specified extreme-performance bonding mortar, engineered for large and heavy adhered veneer installations. This advanced mortar delivers exceptional bond strength, outstanding workability, and robust resistance to sag and efflorescence – ideal for dense, non-porous veneers that demand superior bonding strength. It is the specificationdriven solution for high-load veneer installations, including natural stone veneer, stacked stone, thin brick, tile, plank-style veneers, and manufactured stone veneers.

SVM 500 is a proprietary blend of Portland cement, graded sand, and highly polymer-modified admixtures, engineered to meet or exceed ANSI A118.15 requirements. Developed for demanding adhered veneer installations, it provides the bond strength and durability required for vertical installations nearing the code-approved maximum allowable height for adhered veneers. SVM 500 is fully compliant with ANSI A118.15 for submerged water installations and the optimal bonding mortar for inclusion in the SPEC MIX® SVMS Warranty System. Available in coarse or fine sand blends in standard and custom colors.

Platinum Thin-Set

SPEC MIX® TS Platinum is an extreme-performance thin-set bonding mortar formulated for tile installations involving dense, non-porous units and conditions requiring maximum shear bond strength. This highly polymer-modified mortar delivers exceptional bond performance, outstanding workability, and advanced resistance to sag and efflorescence – making it ideal for vertical tile installations, large-format porcelain tile, natural stone tile, and glass tile.

SPEC MIX® TS Platinum is a proprietary blend of Portland cement, graded sand, and highly polymer-modified admixtures, engineered to meet or exceed ANSI A118.15 requirements and fully compliant for submerged water installations. Developed for challenging vertical or wet environments, it is the preferred tile mortar for inclusion in the SPEC MIX® SVMS Warranty System. Available in 50 lb. (22.6 kg) bags with fine sand blend in standard colors of white and grey.

SVM 300

SPEC MIX® SVM 300 is a high-performance bonding mortar, developed for moderately sized or weighted adhered veneer installations. This polymer-modified mortar delivers advanced bond strength, excellent workability, and enhanced resistance to sag and efflorescence – ideal for less porous veneers requiring strong adhesion, such as natural stone veneers, thin brick, and manufactured stone veneers. It is the preferred solution for installations where veneer units may approach the code-approved maximum allowable height for adhered veneers.

SVM 300 is a proprietary blend of Portland cement, graded sand, and premium polymer-modified admixtures, formulated to meet or exceed ANSI A118.4 and ANSI A118.11 requirements. Developed to provide the bond strength and durability required for vertical adhered veneer installations involving demanding substrates or conditions, SVM 300 is the high-performance choice for inclusion in the SPEC MIX® SVMS Warranty System. Available in coarse or fine sand blends in standard and custom colors.

SVM

SPEC MIX® SVM is a modified bonding mortar formulated for adhered veneer installations using smaller and lighter weight units. Designed for moderately porous veneers, this polymer-modified mortar provides enhanced bond strength over Type S or field-mixed mortars, along with improved workability and resistance to sag and efflorescence. It is ideal for thin natural stone, thin brick, and manufactured stone veneer.

SVM is a proprietary blend of Portland cement, graded sand, and polymer-modified admixtures, designed to meet or exceed ANSI A118.4 requirements. It is an effective choice for inclusion in the SPEC MIX® SVMS Warranty System. Available in coarse or fine sand blends in standard and custom colors.

Technical Data Sheets Available at www.ezmixinc.com.

Mortars and Joint Grouting

SPEC MIX® Type S & M Mortar

SPEC MIX® Type S and M Mortar

SPEC MIX® Type S and Type M Mortars are designed for bedding CMU and full brick units in structural masonry construction, and for grouting interior and exterior applications of stone, thin brick, natural and manufactured veneers, and pavers. SPEC MIX® Masonry Mortars provide a superior product by precisely controlling mix consistency and sand gradation. SPEC MIX® Masonry Mortars are dry, factory-blended mortars manufactured under strict quality control guidelines to meet or exceed ASTM C270, ASTM C1714, IBC, and CBC requirements for type S and type M mortar. Available in 94 lb. (42.6 kg) and 60 lb. (27.2 kg) bags, and in standard and custom colors. One 94 lb. bag lays approximately 22–25 CMU or 40–50 bricks, depending on unit size and job conditions.

SPEC MIX® IWR (Integral Water Repellent) Type S and M Mortar

SPEC MIX® IWR Mortar is engineered for use where a commercial-grade water-repellent masonry mortar is required. It is formulated with integral additives to enhance resistance to moisture intrusion and efflorescence and to minimize shrinkage at the masonry mortar and grout joint. SPEC MIX® IWR Mortar is optimized for bedding CMU and full brick units in structural masonry construction, and for grouting interior and exterior applications of stone, thin brick, natural and manufactured veneers, and pavers. It is manufactured under strict quality control guidelines to meet or exceed ASTM C270 (proportion and property specifications), and ASTM C1714 requirements for Type S and Type M mortar. Available in 80 lb. (36.3 kg) bags and in standard and custom colors.

SPEC MIX® Type S and M Lime Replacement (LR) Mortar

SPEC MIX® LR is a lime replacement mortar mix designed for bedding CMU and full brick units in structural masonry construction, where improved mortar workability and board life are required. SPEC MIX® LR Mortar delivers increased resistance to moisture intrusion, and efflorescence. LR Mortar is ideal for grouting interior and exterior applications of natural stone, thin brick, and manufactured veneers, and pavers. It is manufactured under strict quality control guidelines to meet or exceed ASTM C270 (property specification) and ASTM C1714 requirements for Type S and Type M mortar. Available in 94 lb. (42.6 kg) and 60 lb.(27.2 kg) bags, and in standard and custom colors.

SPEC MIX® Type S and M Lime Replacement (LR) Mortar Plus

SPEC MIX® LR Mortar Plus designed for bedding CMU and full brick units in structural masonry construction, where enhanced mortar workability, and board life are required. LR Mortar Plus is formulated to provide a higher level of resistance to moisture intrusion and efflorescence, ideal for grouting interior and exterior applications of natural stone, thin brick, and manufactured veneers, and pavers. It is manufactured under strict quality control guidelines to meet or exceed ASTM C270 (property specification) and ASTM C1714 requirements for Type S and Type M mortar. Available in 94 lb. (42.6 kg) bags and in standard and custom colors.

SPEC MIX® BASE MORTAR & PMP ACCESSORY PRODUCTS

Base Mortar

SPEC MIX® Scratch and Brown Fibered is a dry, factory-blended exterior stucco basecoat mix designed for plastering contractors. Its precise mix ratio and consistent sand gradation quality make it a superior alternative to jobsite mixes. SPEC MIX® Scratch and Brown Fibered provides superior pumping and troweling performance for the contractor, while delivering a durable plaster finish. The product is a blend of Portland cement, lime, and graded sand. SPEC MIX® Scratch and Brown Fibered meets or exceeds ASTM C926 requirements and is designed for installation over lath for browning masonry walls. The same product is used for the first scratch coat and the second brown coat. Available in 80 lb. (36.3 kg) bags, with coverage of approximately 2.5 square yards per bag.

PMP and SVMS ACCESSORY PRODUCTS

PMP Concrete Bonder & Fortifier is a latex copolymer used either as a paint-on bonder (straight from the bottle) or as a fortifier/admixture (mixed 1:1 with water). It can be added to cement mixes to create flexible concrete and to SPEC MIX® Scratch and Brown Fibered to enhance crack resistance. It improves bond strength to existing surfaces and enhances resistance to moisture intrusion. Available in gallon containers, with a yield of 500-800 cubic ft per gallon.

SVMS Sealant is designed for expansion joints in masonry, stone, tile, and other applications. It is suitable for commercial and residential projects, both interior and exterior. This sealant provides exceptional flexibility and elongation, superior UV resistance, mold and mildew resistance, and is effective for large joints up to 1” (25mm). Available in standard and custom colors.

PMP Spec Concrete 3000 is a dry, factory-blended coarse core fill masonry grout containing cementitious materials and dried aggregates, formulated for superior flow to fill masonry voids. It is a uniformly blended, properly proportioned mixture of Portland cement, graded sand, and 3/8” aggregate. It is used to fill the cells of concrete masonry units and horizontal bond beams, as well as cavities in composite masonry construction. Spec Concrete 3000 may be used in both low and high-lift applications and can be placed by hand or with mechanical delivery. It meets the performance specifications of ASTM C476, Standard Specifications for Grout for Masonry. Available in 90 lb. (40.8 kg) bags.

PMP Grout Additive is a powdered admixture for concrete, used in the grouting of concrete block and clay brick. It will provide slight expansion, retarding, and water-reducing properties to the grout. This product improves grout performance and placeability and does not contain chlorides or other chemicals that promote corrosion of reinforcing steel. It also contributes to higher slump, improved pumping characteristics, and enhanced bond and compressive strength. Available in 42 lb. (19.1 kg) bags.

PMP Concrete Dissolver is a liquid compound specifically formulated to dissolve built-up cement on tools and equipment used in the concrete ready-mix and masonry industries. It is 100% biodegradable and non-corrosive, and safe for use on metals, equipment, wood, glass, vinyl, and painted surfaces.

Technical Data Sheets Available at www.ezmixinc.com.

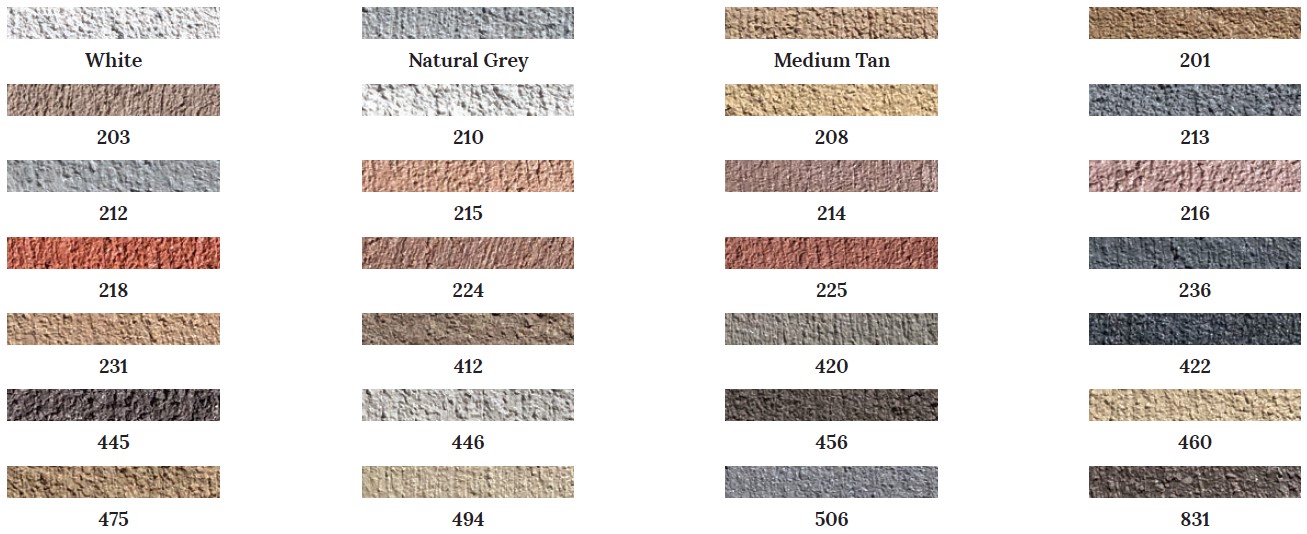

SPEC MIX® COLORED MORTARS

Consistent Colored Mortar Every Time

SPEC MIX® Colored Mortar Quality Assurance Process

Backed by over 30 years of experience, E-Z Mix uses computer-controlled batching to deliver consistently accurate colored mortar. SPEC MIX® Colored Mortar and Grout provides a broad spectrum of color options to meet aesthetic and structural masonry construction demands. To help preserve joint color and minimize surface staining, consider using an efflorescence-resistant mortar such as SPEC MIX® IWR, LR, or LR Plus.

SPEC MIX® Masonry Mortar and Grout is manufactured in standard or custom colors, available upon request.

Note: Colors are subject to variation when viewed in print or digital media.

SPEC MIX® EFFLORESCENCE RESISTANT MORTARS

Don’t let efflorescence ruin your project!

Here’s how to protect your next project – big or small – from efflorescence.

SPEC MIX® Integral Water Repellent (IWR) and Lime Replacement (LR or LR Plus) Mortars are premium waterrepellent masonry mortars formulated with specific additives that significantly enhance resistance to moisture intrusion, thereby minimizing efflorescence and improving overall performance.

Key Benefits:

- Exceeds ASTM C270 Type S and Type M (property specifications) and ANSI A118.6 requirements.

- Resistant to Efflorescence – Minimized staining and lower risk of cracking.

- Exceptional Workability – Flows easily through a grout bag, ensuring smooth application.

- Versatile Colors – Available in a variety of standard and custom colors to match your project needs.

SPEC MIX® IWR, LR, and LR Plus Masonry Mortars are used for bedding CMU and full brick units in structural masonry construction, and for grouting interior or exterior applications of natural and manufactured veneers, stone, thin brick, pavers, brick, and precast.

By choosing SPEC MIX® IWR, LR or LR Plus Masonry Mortars, you’re selecting a high–performance mortar designed to offer both durability and aesthetic flexibility.

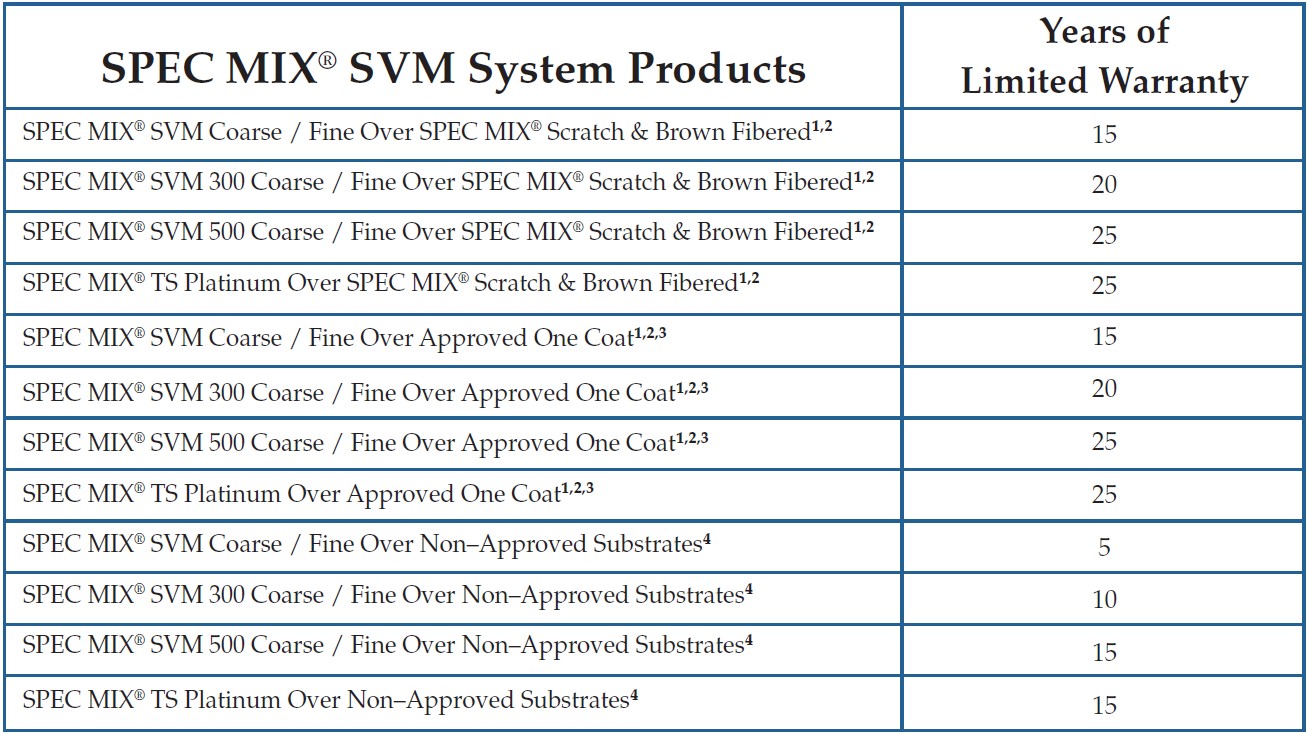

SPEC MIX® SVM SYSTEM LIMITED WARRANTY

E-Z Mix strongly stands by the reliability and performance of the products we manufacture, and therefore, E-Z Mix provides the following limited warranty for our SPEC MIX® SVM System subject to the terms, conditions, and limitations set forth herein:

Covered Products:

This Limited Warranty applies to the following products (the "Covered Products") for the following time periods:

E-Z Mix offers extended Limited Warranty coverage – up to an additional five-years – when the following components are used in conjunction with the Covered Products. These extensions may be combined, allowing for a maximum total extension of up to ten-years when multiple qualifying components (such as footnotes1 and2) are used together.

1 Water and Air Barrier – Use of a code-compliant and approved water and air barrier meeting ICC-ES AC212 requirements qualifies for an additional five-year warranty.

2 PMP Acrylic Concrete Bonder & Fortifier Admix – When used in accordance with manufacturer guidelines and with an approved One Coat Base Coat or SPEC MIX® Scratch & Brown Fibered qualifies for an additional five-year warranty.

3 Approved One Coat Base Coat, please contact E-Z Mix Technical Support: tech.support@ezmixinc.com

4 Code-compliant and properly installed lath, fasteners, control joints, and flashing, along with properly prepared substrates – including but not limited to CMU, cement backer board, and poured-in-place concrete – are required for warranty compliance.

5 Angelus Block CMU – Use of Angelus Block Co., Inc., concrete masonry unit as the substrate qualifies for an additional ten-year warranty. This extension is independent and cannot be combined with coverage offered by components noted in footnotes1 or 2. Referenced on page 11.

For exact and requisite details of our full SPEC MIX® SVM System Limited Warranty program, please refer to our E-Z Mix website at www.ezmixinc.com/SVMS.

Industry Resources

Below is a list of industry resources related to proper veneer installation methods, substrate preparation, and best practices: Review these resources before starting a veneer installation project or to troubleshoot issues if a failure occurs.

- ASTM C1780 – Standard practice for installation methods for adhered manufactured stone masonry veneer

- CMHA – Manufactured stone veneer installation guide and detailing options for compliance with ASTM C1780

- BIA Technical Notes 28C – Thin brick veneer installation

- TCNA Handbook – Proper installation methods and details

- Local Building Codes – CBC and OSHA requirements

- Install in accordance with ANSI A108.5 standards

SPEC MIX® by E–Z Mix For High–Quality, Effective Solutions for Your Masonry Veneer Projects

For additional information please visit our website at ezmixinc.com or ezmixinc.com/SVMS

- Complete, updated product catalogs

- Downloadable product tech data sheets and SVMS specification in Word format

- Email online sample request www.info@ezmixinc.com

- Warranty information

Locations

Corporate Office:

11374 Tuxford St., Sun Valley, CA 91352

Sun Valley Plant:

11450 Tuxford St., Sun Valley, CA 91352

Rialto Plant:

3355 S. Industrial Dr., Rialto, CA 92316

Website: www.ezmixinc.com

Email: info@ezmixinc.com